Grinding Aids for Ball Mills | Industrial Efficiency ...

A grinding aid prevents this agglomeration to improves the grinding efficiency. ... Grinding Aids for Ball Mills Publications.

WhatsApp)

WhatsApp)

A grinding aid prevents this agglomeration to improves the grinding efficiency. ... Grinding Aids for Ball Mills Publications.

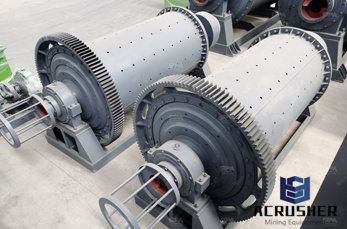

Ball mills are giant drums that are filled to between 30 and 40% of their volume with freely moving grinding media in this case balls. The diameter of the balls is ...

what is agglomeration mill ? Ball mill – Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into ...

ticle due to agglomeration ... Tumbler ball mills Large scale production of Consumption and ... a novel route to novel materials with controlled nanostructure ...

ball mill nano particle. Ball Mill ... Jet mills, Hosokawa Micron, Nano Particle Technology, Classifiers, Agglomeration, ...

These days high energy ball mills are being used for particle size ... hindrance between ZnO particles for preventing it from agglomeration which happened in wet ball

Additives are typically ground in either air swept vertical roller mills or horizontal ball mills, ... It is basically an agglomeration process achieved through ...

fritsch Ball Mills ... • Agglomeration phenomena avoided • Ergonomically positioned membrane keyboard IP65, splashproofed • Recyclable plastic housing

Improved Jc of MgB2 superconductor by ball milling using different ... In this paper, the effects of ball milling B powders using different media, such as ...

Glass beads (small balls) and balls were developed specifically for grinding applications where sand wasn

Aug 02, 2007· can anybody tell me how to design ball mill Help; Remember ... Ball Mills refer to ... does anyone know how to designor select lifter bars for a agglomeration .

Traditional vertical mills and ball mills are often ... eliminate particle agglomeration and reduce the ... about horizontal vs vertical mill ...

You are here: Home Mills Cement Mill Ball Mill Dynamics. ... material agglomeration in the mill and "pack set". Ball and liner .

Deagglomeration Industrial Sand Processing Plant | Mineral . DeAgglomeration. Many times reserves are found that are actually agglomerated grains of sand. .

agglomeration in ball millsartificial sand making machine tamilnadu,double head motor bench grinding machine,mineral iron ore daily price in malaysia,portable rock ...

Supply Sintered Process Of Agglomeration Of Iron Ore. ... XSM grinding mills vary from coarse grinding, ... Ball Mill Raymond Mill Coarse Grinding Mill.

The primary step in size enlargement is agglomeration, the formation of a ball or sphere by ... Pellet mills are used in ... Particle Size Enlargement ...

Can planetary ball mill grind particles to the size smaller than micron? Yes, the size of particle can be smaller than ... How to prevent agglomeration?

Unlined steel, alumina and rubber lined ball mills are available. ... Dispersion, Emulsification, Homogenization, Deagglomeration Disintegration, ...

Nano Sizing Via Wet or Dry Grinding Nanosized particles are ... In deagglomeration, ... it is possible to achieve nanosized particles through jet mills operated ...

Savona Equipment is your source for New, Used, and Reconditioned Agglomerators for cyanide heap leach plants to smaller heap leach plants. Refurbished Agglomerator ...

Home > Iron Ore News, Iron Ore Mining, > agglomeration of iron ores ball. Crushing Equipment; Grinding Equipment; ... Mineral Grinding Mills on .

Some devices, such as ball mills, are more suitable for coarse materials. These mills use "large" media, ranging in size from 20 mm in diameter ... agglomeration.

A cement mill (or finish mill in ... Ball mills are normally operated at around ... The bed of material drawn between the rollers emerges as a slablike agglomeration ...

WhatsApp)

WhatsApp)