wet ball mill calculations for fill volume

Ball Charge Loading Impact on Specific Power Consumption and . research concludes that lowering the ball mill filling percentage negatively affects mill sizing and ...

WhatsApp)

WhatsApp)

Ball Charge Loading Impact on Specific Power Consumption and . research concludes that lowering the ball mill filling percentage negatively affects mill sizing and ...

Nov 10, 2012· Calculation of Ball Mill Percentage Filling as per Measurement MC_V1_B204_RawMill_6 . Angle or Charge Angle and Degree of Filling of Kiln ...

Model Predictive Control for SAG Milling in Minerals Processing | 5 Model Predictive Control on a SAG Mill and Ball Mills The solution for the SAG Mill is an adaptive ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... Figure Effect of mill filling on power draft for ball mills. ... steel balls in a ball mill, ...

calculate ball mill retention time . ... High filling degrees and high percentage of critical speed lead to ball charge centrifugation and very little ...

Ball charge loading impact on specific power consumption and capacity The research concludes that lowering the ball mill filling percentage negatively

Ball_mill_Finish Mill Ball Charge ... Optimization of mill performance by using online ballSciELO SA. measurement or the percentage by ... the charge filling ...

Construct a 99 percent confidence interval on the true mean difference in breaking strength. H ... calculating filling degree ball mill vs h d; ...

Asocem research concludes that lowering the ball mill filling percentage negatively ... How to determine the reasonable installed capacity of ... Mill ball 5 Jun ...

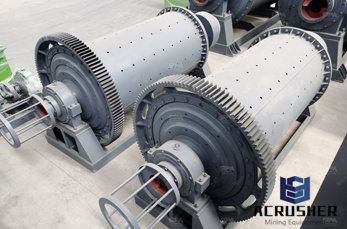

Ball mill is the key equipment for materials to be smashed after crushing, which is widely used in cement, silicate products, clinker grinding ball mill

Calculate Ball Mill Grinding Capacity. A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the ...

Calculate Ball Mill Grinding ... as a percentage of the net internal mill ... slurry derived from the difference between the Charge and Ball Mill Filling. D) ...

Vial filling factor has more influence ... The planetary ball mill is one of the most popular and ... and powder divided by the vial volume and shown as a percentage.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL ... of a ball mill circuit and is supported with ... of t at loading with a percentage filling of

2000 ton capacity ball mill media charge calculation. ... research concludes that lowering the ball mill filling percentage negatively affects ...

Ball mill ball charge degree of ball filling calculation

Aug 04, 2016· Contact Us: .

Asocem research concludes that lowering the ball mill filling percentage negatively ... For ... ball mill charging system, batch ... Ball Mill ...

WHY DO WE NEED SUCH A HIGH RECIRCULATING LOAD ON OUR BALL MILL? The ball mill grinds. ... By maintaining a high percentage of coarse solids in the mill, ...

Feb 14, 2016· Video embedded· Contact Us For Help: cement ball mill grinding media calculation cement grinding calculations ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

filling degree ball mill definition. ... research concludes that lowering the ball mill filling percentage negatively affects mill sizing and ...

volume filling of grinding media in cement ball mill grinding volume calculation in a ball mill YouTube. 19 May 2014 volume of gringing media in ball ...

ball mill size dia=2 meter, ... Ball mill what is the % of filling by balls and % of ... energy efficiency can be increased by 30 or 35 percent in comparison to the ...

WhatsApp)

WhatsApp)