Ball Mill Critical Speed | Mill (Grinding) | Cement

/S"1 International Mining Congress and Exhibition of TurkeyIMCET 2003, (c 2003. ISBN The Effect of Fraction of Mill Critical Speed on Kinetic Breakage ...

WhatsApp)

WhatsApp)

/S"1 International Mining Congress and Exhibition of TurkeyIMCET 2003, (c 2003. ISBN The Effect of Fraction of Mill Critical Speed on Kinetic Breakage ...

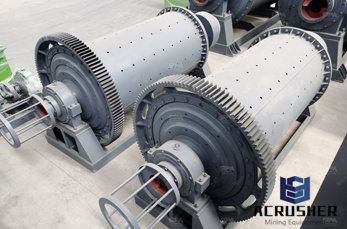

We are supplier and manufacturer of Ball Mills, Horizontal Ball Mills, perimeter of mill (this point is called "Critical Speed" ball mills normally operate at 65% to.

Mill Speed Critical Speed Paul O. Abbe. Mill Speed Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing ...

How did you derived the formula for the critical speed of the ball mill?

Sep 17, 2017· Feed Back. Rod mills, how they function Mine The Critical Speed is used for the determination of ball mill ideal operating speed.

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

critical speed of the ball mill. Ball Mills Mine This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently ...

Derivation of critical speed of grinding mill – The QA wiki. What is critical speed of a SAG mill? The critical . is two latticetype ball mill. The materials ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... The critical speed of the mill, ... Figure Effect of mill filling on power draft for ball mills.

ABSTRACT: In this study, the effect of fraction of mill critical speed was investigated on the limestone and the clinker samples using Göltaş cement factory ...

TECHNICAL NOTES 8 GRINDING R. P. King Mineral Technologies . The critical speed of the mill, c, is defined as the speed at which a single ball will just remain ...

Derivation Of Critical Speed Of Ball Mill Mp3 Found 0 files Derivation Of Critical Speed Of Ball Mill Mp3 Download for free... Chat Now! gearbox ball mill instalation ...

Critical Speed of Ball Mill For a ball mill, it does not have a constant critical speed, because of the centrifugalization of the steel balls is different accor

Critical speed can be ... Aside from common ball mills there is a second type of ball mill called a planetary ball mill. Planetary ball mills are smaller than ...

Industry News. ball mill critical speed best ball mill critical speed. Buy quality ball mill critical speed products from ball mill critical speed manufacturer ...

A cement mill (or finish mill in ... Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will turn at around 14 rpm.

Original document English (PDF 367kb) ,ABSTRACT: In this study, the effects of ball charge, powder filling, mill speed and while it asymptotically increased ...

Ball Mills Mine information on ball mills ... This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Ball Mill Operating Speed Mechanical. In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding. Presently, for the ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

WhatsApp)

WhatsApp)