Influence of beneficiation plant pellet grade iron .

white paper 2013 3 Table 3 Raw material mix proportion Description % Mix 1 Iron ore LimestoneDisc operating angle : 45 Bentonite Coke breeze,% image at different places phases identified ...

WhatsApp)

WhatsApp)

white paper 2013 3 Table 3 Raw material mix proportion Description % Mix 1 Iron ore LimestoneDisc operating angle : 45 Bentonite Coke breeze,% image at different places phases identified ...

Contents • India – Steel Production and Iron ore scenario • Why Utilization of Iron ore fines • Essar''s contribution in utilization of iron ore fines slimes • Benefciiation • Agglomeration • Slurry pipeline transport • Essar''s BF operation ...

23 Anticipating Technology Directions Exploration, mining, mineral dressing Development of innovative alternative ironmaking process technologies to use low grade, low cost resources and to reduce the level of air pollution

SECTION 1 AN OvErvIEw Of ThE SOuTh AfrICAN IrON ANd STEEl vAluE ChAIN ExECuTIvE SummAry 1 CONTExT ANd purpOSE 2 dESCrIpTION Of ThE vAluE ChAIN 2 IN SOuTh AfrICA ore price as a ...

The Mining Process as it pertains to the Trust of Great Northern Iron Ore Properties The Trust of Great Northern Iron Ore Properties previously received royalties primarily from the mining of taconite ore from its properties by the Trust''s ...

4 2 Materials Used to make Steel Iron Ore Composition Iron very rarely occurs in the earth''s surface as a metal. It is widely distributed, combined with oxygen as iron oxides. In fact it is believed that iron makes up about 5% by ...

Waste oxide agglomeration Harsco Metals Minerals Micropelletized steel mill byproducts can be directly inserted into the sintering process, as a substitute for lowgrade iron ore or scrap. In conjunction with direct Get Price ...

During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material. By beneficiation is meant all methods of removing impurities, and raising the iron content to a ...

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi ...

Mining Industry: What is iron ore beneficiation? . Iron ore beneficiation is a multistage process that raw iron ore undergoes to purify it prior to the Methods such as screening, crushing, and grinding of iron ore are often used in Low ...

SEAISI 2002 – "Improvement of Product Quality and Environmental Control by the Utilisation of Advanced Technologies in the Iron and Steel Industry" 1 HIsmelt The New Technology for Iron Production BY TARA GOLDSWORTHY*

Magnetite vs Hematite Hematite Traditionally, the Australian iron ore industry has been based on the mining, production and export of highgrade hematite ores which currently account for approximately 96% of Australia''s iron ore ...

Lowgrade iron ore may help tackle India''s steel headache | Reuters 12 Aug 2013 ... Mining curbs force steelmakers to use lowgrade iron ore fines ... and Steel Authority of India, are investing in plants that can process lowgrade...

Evolution of the extracted iron ore grade in different countries (Canada, China, Australia, Brazil, United States, Sweden, USSRRussia, world). The recent drop in world ore grade is due to the big consumption of low grade ...

2013/08/12· Indian steelmakers are making a big push to use locally mined lowgrade iron ore fines that are usually exported, a move that could help the world''s No. 4 steel producing nation boost nearstagnant domestic output and ...

uses of extremely low grade iron ore uses of extremely low grade iron ore. is one of the biggest manufacturers in Aggregate Processing Machinery for the pictures of ball mill for iron ore, sand Get Price Online the process of ...

Iron ore price: It''s all about grade now, Iron ore is down 30% this year and after a relatively quiet 2013, market volatility is back with a vengeance. The market was jolted on March 10 this year, when iron ...

Why does the DR process require specific iron ore types? • DRprocess does not form a liquid slag in the same way BFprocess does • Impurities are concentrated – rather than removed • Therefore only highpurity, low gangue, iron ...

Feed Back Iron ore definition of iron ore by The Free If there be iron ore, and streams whereupon to set the mills, iron is a brave commodity where wood aboundeth. Chat Online Hematite Iron ore beneficiation process flow FDM ...

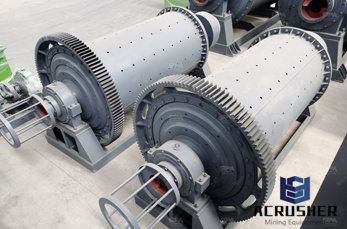

Grinding mill: Uses: Attrition between grinding balls and ore particles causes grinding and can be used after ball mills in a grinding process. Like ball » Learn More Iron ore mining process Crushing equipment: crusher ...

327 Iron and Steel Manufacturing Industry Description and Practices Steel is manufactured by the chemical reduction of iron ore, using an integrated steel manufacturing process or a direct reduction process. In the conventional ...

Iron Ore Processing for the Blast Furnace – Steel Org Creating steel from lowgrade iron ore requires a long process of mining, . Each primary mill contains several 4" steel balls that grind the ore as the mills turn.

Published Feb 24, 2015 Ecoefficient and costeffective process design for magnetite iron ore Currently, the mining industry is facing several issues related to energy consumption so the optimized use of energy is an everincreasing ...

1 Influence of high grade iron ore usage on the performance of SEA Blast Furnaces BY OLIVEIRA, M. VINICIUS *; KUMAR, PRACHETHAN **; OLIVEIRA, DAUTER. *** SYNOPSIS With growing demand for steel in the region of ...

WhatsApp)

WhatsApp)